6 inventory control techniques for stock optimization

Inventory control techniques that use stock optimization best practices

There are hundreds of inventory control blog posts on how to organize warehouses, track goods and pick and pack efficiently. So we thought we’d focus on the lesser known topic of ‘stock optimization’ – this is an inventory control technique that’s becoming more popular with inventory managers to improve the efficiency of their supply chain.

Firstly, let’s get a few definitions:

What is inventory control?

Inventory control is the process of managing and regulating the supply, storage and distribution of stock. Inventory control is a key function of supply chain management that maintains appropriate quantities of stock to meet customer demand.

What is stock optimization?

The objective of stock optimization is to have the right products in the right place at the right time – as efficiently and cost-effectively as possible. Stock optimization (also known as inventory optimization) plays a key role in ensuring inventory control techniques can be carried out effectively. It’s the art of achieving stock availability, while reducing inventory costs and minimizing the risk of excess items. This is done by forecasting demand and managing supply variables while dynamically adjusting stock rules and inventory parameters.

We all know that inventory takes up valuable warehouse space and ties up capital. Therefore it’s important to invest money in products that will sell so you can optimize inventory turnover and warehouse space.

In this post we’ll look at 6 inventory control techniques that will specifically show you how to control your stock levels, help you optimize your inventory and maximize profits.

6 inventory control techniques to optimize stock levels

1. Understand your demand

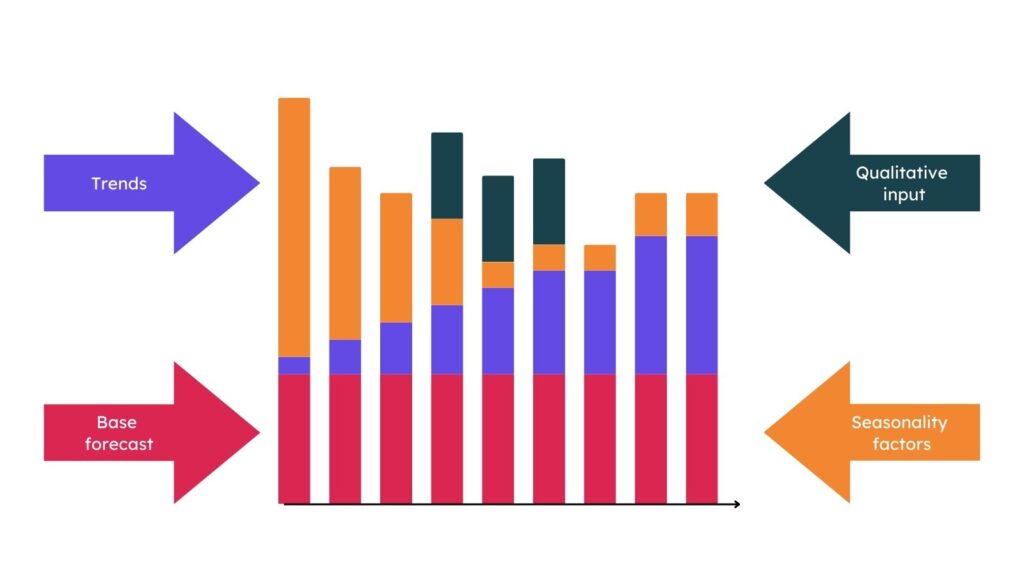

Our first inventory control technique is all about demand forecasting. The key to controlling your stock levels is knowing what products to carry to satisfy market demand. It’s critical to invest time (and money if required) in setting up advanced inventory forecasting models that produce accurate demand forecasts. It’s not enough to look at last year’s sales figures and expect this year’s to follow the same pattern! Effective forecasting should consider:

Product lifecycles: every item in your warehouse is sitting at a specific stage in its product life cycle. Each life cycle stage will affect the item’s demand pattern and so needs to be considered when forecasts are being calculated. Read our blog on demand forecasting accuracy for more details.

Seasonality: identify any products in your portfolio that have seasonal demand variations. It’s best practice to keep seasonal demand factors separate from your base demand calculations. This keeps the data clean and easier to use for forecasting going forward.

Trends: Product demand is influenced by fashion, technology, social, economic and legal factors. Look out for such trends in your historical demand data and adjust your forecasts accordingly.

Qualitative factors: Add any qualitative forecasting factors into your data, such as sales promotions, competitor activity or external market events.

Many factors cause demand variability – read our eGuide for the lowdown:

2. Know your star products!

ABC analysis is a good inventory control technique to segment your warehouse stock based on the value it brings to the company. Every item in your warehouse has a different value in terms of how much money it makes the business. There are many ways to define ‘value’, including segmenting based on sales revenue, profitability, sales volume or annual consumption value. Choose one that works for you. Then split your stock into categories: A, B, and C. ‘A’ being the items that are critical to your businesses success and ‘C’ being those that are least important.

ABC classification is a simple way to identify your most important products so you can focus your time in terms of stock control and management. In addition, it can help you set out more focused stock control parameters (see next point!)

It is, however, a very simplistic framework and fails to account for supply and demand variables. For more complex inventory classification, use inventory optimization software, which carries out multi-dimensional item categorization. By segmenting SKUs based on their demand, inventory turnover and their profitability you can get a much greater insight into controlling your stock levels.

3. Set stock level control policies

Inventory policies ensure you’re stocking the right goods in the right quantities – a must for good inventory control in the warehouse. Make sure you have a set of ‘rules’ for every SKU you carry. Inventory classification, such as

ABC analysis, will help with this. For example, you should consider setting different service levels, safety stock levels and reordering parameters for each category.

Don’t forget to have a policy for reducing excess stock and removing obsolete items. While excess stock has a negative impact on stock turnover and eats into working capital, if it becomes obsolete it’ll also gnaw away at your profit margins too!

There are only six points in this post, so here’s point 3b – set useful inventory KPIs! While this might sound obvious, it’s worth reviewing your current KPIs to ensure they’re helping to add value to your operations in terms of meeting business objectives and improving efficiency, customer service and profitability.

4. Introduce service level targets to optimize stock

A target service level measures the probability of having the correct quantity of an item in stock when it’s requested for delivery, leading to a completely fulfilled order.

When setting target service levels, consider your customers’ expectations in terms of availability and delivery times. For example, if a seven day lead time is acceptable to your customers, then you might be able to lower your inventory levels and rely on smaller purchase quantities, reducing tied-up capital, or you could place on-demand orders with your suppliers if they have short lead times to you.

Remember – providing higher service levels than required costs your company money. Failing to meet customer expectations, however, can lead to lost sales and a damaged reputation. So you need to find a balance!

Service levels will also influence your stock turnover rate – aim for higher service levels on faster moving items and lower them for those with less demand, so you can keep your turnover rate high and avoid tying up capital unnecessarily.

5. Fine-tune your stock replenishment strategies

You can only optimize stock levels when you have informed inventory purchasing practices.

Most businesses will reorder either when they hit a fixed date or when stock drops to a specified level – the defined reorder point. The amount they reorder is usually either a fixed amount or variable to meet a minimum or maximum stock capacity. Many ERP and WMS systems will use one of these approaches. However, if these methods are leading to stockouts or excess stock scenarios, you need to look for a smarter way to carry out replenishment. A more ‘informed’ or dynamic approach is to factor in the following variables:

- Demand forecasts

- Supplier lead times

- Cost-effective order quantities

Introducing supply and demand variables into your stock replenishment strategies will help the accuracy of your ordering and prevent stock build-up.

6. Carry safety stock to reduce risk of stock outs

Safety stock, also called buffer stock, is the layer of inventory kept to prevent stockouts and back orders in situations where the forecast is exceeded or supply is delayed. Safety stock minimizes disruptions caused by demand, supply chain or fulfillment disruptions – while investing the lowest possible amount of capital in inventory.

Many businesses (WMS and ERP systems) still use a basic stock days model to calculate safety stock e.g they work out the number of days (or weeks) of demand and add enough buffer stock to cover any variance – for example, 4 weeks of cycle stock and 2 weeks of safety stock.

But – this “one size fits all” approach assumes that all goods in the warehouse have similar demand patterns and behave the same. As we’ve already discussed, this is most certainly not the case. The more accurate you can make safety stock calculations, the less likely you are to experience out-of-stocks or overstocking situations. When calculating safety stock, the most important factors to consider are:

- The desired service level

- Forecasting accuracy

- Lead time (or delivery variation)

The best inventory control methods use stock optimization tactics

It’s impossible to optimize your stock levels without considering supply and demand variables. Effective inventory control techniques therefore rely on stock optimization tactics.

Many businesses use standard ERP or WMS systems to execute their stock control procedures while others still resort to spreadsheets. Both approaches, however, have their limitations in terms of functionality. More and more businesses are therefore turning to inventory optimization software to automate their processes and improve efficiency. Inventory optimization tools use advanced algorithms that are simply not available elsewhere to bring accuracy and speed to inventory management calculations.

Ok, so this may sound expensive and it’s true that enterprise-level inventory software systems are way beyond the budgetary reach of many smaller businesses. However, EazyStock is a best-in-class solution – born from one of these larger platforms – that is specifically designed for businesses of all sizes. It is affordable and still delivers sophisticated, dynamic functionality.

As an ERP plug-in, EazyStock is easy to set up and offers actionable inventory cost reductions and service level improvements within weeks of implementation.

For more information on how your inventory control practices could benefit from EazyStock, or to book a demo, please get in touch.

Blog post originally published Aug 2015; updated Oct 2020.