Supplier Selection Criteria & Process Explained

In the wholesale distribution of nonperishable goods, a winning strategy is key to ensure profitability of the operation. Throughout the supply chain, costs must be minimized and revenue maximized. To ensure that purchasing and warehouse costs remain low, strategic supplier selection is an important consideration.

What to consider when choosing a supplier

There are a number of aspects to consider when choosing suppliers:

Price

The primary consideration is the cost of the goods. While it is essential to negotiate the lowest unit price, there are other cost factors to consider, such as the provision of bulk discounts and the cost of delivery.

Service

This ties in with price; there is a fast-moving supply chain in wholesale distribution, and a reliable supply of goods is essential to prevent stock outs. It is also important to avoid overstocking, so discounts for bulk orders need to be balanced against inventory cost reduction to avoid negating the benefits. Supplier reliability is therefore essential to optimize order points for maximum profitability.

Quality

This should never be compromised for the sake of price and reliability. Poor quality goods will tarnish the wholesaler’s reputation, leading to reduced revenue. With strategic supplier selection, the organization should seek instead to obtain value for money.

Alignment

The choice of suppliers should be aligned with the strategic goals of the organization – this is to say that they should be able to supply the goods in such a way as to fill the supply needs of the operation. In wholesale distribution, it is essential that suppliers’ capabilities facilitate inventory optimization.

Risk

A supply chain optimized for maximum efficiency is vulnerable to disruptions in supply. Suppliers closing down or being acquired can have negative effect, so potential risk is a major consideration when choosing a supplier.

The process of supplier selection

Step 1: analysis of company needs

This takes alignment into account; it is essential to know the criteria for supplier selection, and this involves knowing the needs of the business. In the first instance, suppliers will need to be able to supply the goods that the organization sells. Other considerations are the relative stock turnover of different items, whether there is a need for bulk supply, whether there is a requirement for bespoke or specialist items, and whether certain items will need to be bought as single units.

Step 2: request for quotation

The second stage involves contacting suppliers and discussing the criteria with them to establish those that fit the organization’s requirements. Suppliers will be invited to give their best proposals and, having established a short list of suitable candidates, further discussion will be necessary to establish ideal lead times and to negotiate discounts.

Step 3: supplier management

Having taken care to ensure that suppliers align with company needs, there should be a process of ongoing evaluation to ensure that they are continuing to aid the organization in achieving its goals. Supplier management can also mitigate risk by highlighting those suppliers that are going through changes that may negatively impact operations. As the organization develops and grows, ongoing evaluation can aid in ensuring that the supplier base continues to be a good fit for company strategy.

Supplier Relationship Management (SRM)

Multiple suppliers and multiple product lines will make keeping track of suppliers and their performance difficult; this is where SRM software can prove essential. Supplier systems can help to maintain a two-way relationship with suppliers, enabling them to grow and adapt to the changing organizational needs.

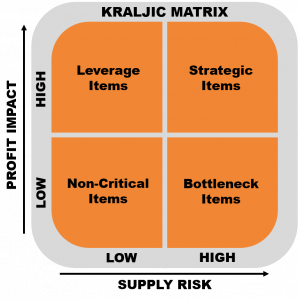

A system overview can enable the organization to evaluate product lines and their respective suppliers according to the Kraljic matrix, which evaluates items based on supply vulnerability and value to your business. By evaluating your inventory based on these guidelines, the appropriate supplier management can be streamlined.

Supplier systems that are optimized to this matrix can enable the organization to ensure a good fit between the needs of a growing profit range and suppliers while maintaining ongoing relationships. Effective SRM will also serve to keep both supplier and customer happy with expectations clearly outlined and processes streamlined.