AL-KO Gardentech UK cut stock by 20% as service levels hit 99%

AL-KO Gardentech is a powerhouse in gardening equipment.

As a leading developer and manufacturer, they continually innovate and create quality products, such as electric, battery, petrol and robotic lawnmowers, as well as one of the market leaders for garden tractors.

However, with thousands of SKUs and a global network of suppliers, it’s not surprising that AL-KO Gardentech UK found inventory management complex.

The challenge

AL-KO SKUs fall into two categories: they have around 400 machines or finished items and an eye-watering 250,000 spare parts (although not all of them are active).

Lewis Anderson, Head of Sales Marketing, was experiencing two fundamental problems with stock management – prolonged stockout periods and excess stock. This led to poor service levels and a tendency to order stock ‘just in case’, even when the warehouse had sufficient stock.

With the implementation of Microsoft NAV as their new ERP system, AL-KO was hopeful they could use it as a stock-planning system. However, the default system wasn’t suitable, and they realised that if they implemented all of their required customisations, they’d be back to a Frankenstein-type system they’d just replaced!

That’s when Lewis and Managing Director, Stewart Anderson, decided to look for a more specialist solution to help them achieve their goals of:

- Improving overall service levels to provide the best support to their customers.

- Improving their use of working capital to ensure they invested in goods they knew would sell.

The solution

While Microsoft NAV suggested some stocking planning apps, Lewis and Stewart quickly realised they weren’t up to task. Their basic and linear models meant that they looked at stock levels and historical sales data to predict future sales. Unfortunately, this simple 30-day rolling average forecasting model only works in stable markets when demand doesn’t fluctuate, which isn’t very common.

Instead, Lewis decided to look for specialist software and found EazyStock. “At the end of the day, why would you go to an ERP business to get specialist stock planning software?”

Not only did EazyStock stand out with its functionality and capabilities, but Lewis loved the flexibility of setting up each item independently and tailoring it to AL-KO’s needs. Being a cloud solution was perfect for Lewis, especially when travelling. “I liked that it was on the cloud, so you don’t have to worry about connecting to a VPN. Stewart and I travel a lot, and you don’t have to worry about connecting to a VPN; you can access it from any browser anywhere.”

Not only is EazyStock accessible from anywhere in the world, but it also works across various devices, which makes Lewis’s life much easier. “I use it on my iPad all the time. As I use a Mac, when I want to log into the ERP system, I have to use a remote desktop, but the cross-functionality of EazyStock is so good, it works on anything.”

Lewis also loves how quickly he can get the information he needs. “You don’t have to wait to run a report or view the dashboard. You just click it, and it’s there.”

The results

AL-KO are capitalising on EazyStock’s advanced algorithms and capabilities to achieve their objectives, and the results speak for themselves:

Thanks to EazyStock’s advanced algorithms, forecasting is no longer linear. Instead, EazyStock considers various factors and highlights trends and spikes in orders so Lewis knows the data is accurate and can trust the recommended orders.

Connecting EazyStock to Microsoft NAV makes it much easier to check data, avoiding the need to run manual checks in Excel. With more accurate forecasting, service levels have reached an all-time high and backorders and associated costs remain consistently low.

“As a seasonal business, we take pre-season orders for the upcoming period, which are received daily. With so many SKUs, we can’t keep on top of them all, but EazyStock adjusts the data daily, so we don’t have to wait until the end of the month or quarter to get the data. Instead, I log in, check my saved searches, hit a button, and bang, there’s your recommended order.”

Lewis found they were running out of a lot of relatively low-value items, which cost a lot in the additional carriage for daily backorders. This is where EazyStock’s inventory policies came to the rescue.

Working with AL-KO’s dedicated customer success manager, Mark Chapman, Lewis classified all items using ABC analysis. With all items grouped as A, B, C, D or E, EazyStock can recommend stock levels for each, which has boosted fulfilment rates and seen carriage for backorders plummet.

“If an item was on backorder, we could spend double the order cost in carriage, which is ridiculous. With higher fulfilment rates, we’re sending fewer packages, which reduces carriage and packaging costs and is more convenient for the customer, making AL-KO a trustworthy and reliable brand.”

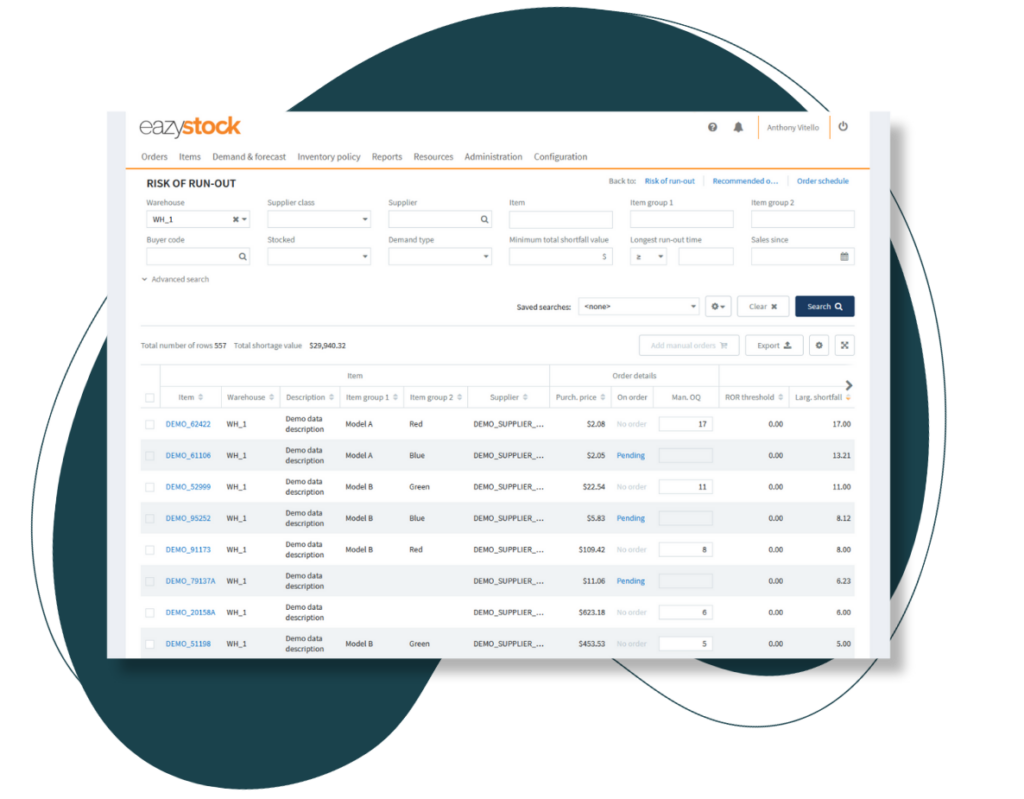

In Lewis’s words, “the risk of run-out report is class.” Entering supplier lead times for items allows EazyStock to alert Lewis when an item needs reordering, which means he can prevent a stockout and maintain service levels. This additional visibility enables strong supplier relationships as they receive orders within their lead time, which helps them provide a good service.

“When EazyStock sends an alert, I can contact the supplier and see if they can add extra items to an existing order or place another order. The risk of run-out report has enabled us to maintain a 100% fulfilment rate for over a year for one brand, which is amazing. Our customers can trust us to deliver.”

EazyStock will flag outliers or anomalies in sales orders so it’s easy to check whether to include the data in forecasts. Lewis now reviews the outlier report every four weeks to ensure data and forecasts remain accurate.

“Being able to check this information regularly makes it much easier to identify the reason for the outlier and keep on top of it. I’ll know whether that was a one-off for a customer, whether it’s a new product, genuine outlier or an error.”

Lewis has nothing but praise for the support he’s received from his dedicated customer success manager, Mark Chapman. Mark has been involved with the project from the start and works closely with Lewis to get the most out of EazyStock.

“Mark has helped from the beginning with getting our data sorted and set up. It’s great to have the consistency of working with the same person and not being passed off to a generic help desk.”

“It’s really important for us to build relationships with our customers and get to know their business. We can’t provide the best service if we don’t have that level of understanding, and maintaining a long-term customer success manager relationship is essential to helping our customers meet their goals,” says Mark.

When asked what advice he would give to companies thinking about optimising their inventory, he says, “You get out of it what you put into it. Work with your customer success manager to tailor the system and get the best out of the system.”

“You don’t have to do everything at once,” confirms Mark. “We can help you bring value in stages and ensure you overcome your inventory management issues.”

Overall, AL-KO has harnessed the power of EazyStock to achieve their objectives, positioning themselves as a formidable force in the gardening equipment industry.